flexible airfoil

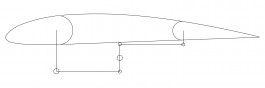

Construction, implementation and first tests of a flexible airfoil for rotor blades of wind turbines. The wing was designed especially for tests in the wind tunnel, so that it could be used to determine the stall behavior and pressure measurements over the leading edge.

Type: Bachelor Thesis

Institut Fluid Mechanics and Aerodynamics, TU Darmstadt

Year: 2015

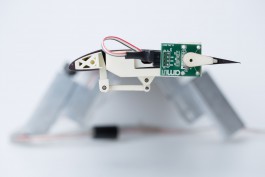

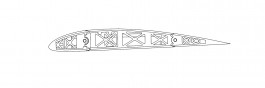

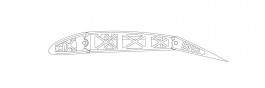

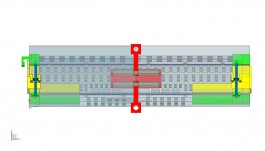

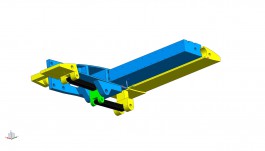

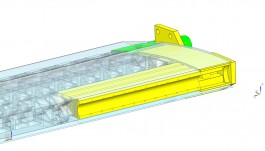

My task of the bachelor thesis was to build a flexible airfoil profile for experiments in the Eifelkanal of the Tu Darmstadt, to put it into operation and to realize first experiments. The SLA invented the concept for the flexible airfoil for wind turbines in order to reduce strong load fluctuations on rotor blades. The profile is equipped with a front and a rear flap, which are mechanically coupled to each other. If a strong aerodynamic load is applied to the wing, the front flap is lifted, and the entire profile is unwound by the coupling. This reduces the lift force of the profile and reduces the peak load.

Construction

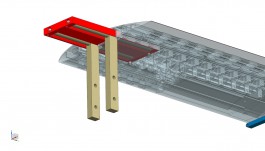

The biggest challenge was to integrate the coupling mechanism into the wing. Since the chord length is very small, the lever arms were too short, and the mechanism was positioned on the underside of the wing. Another challenge was the adjustable spring stiffness of the mechanics. This was solved in such a way that inserts could be inserted into the torsion springs on the sides and the total spring stiffness was determined by the number of springs. The attachment to the linear motors, with which the angle of attack of the wing is defined, was realized via two connecting parts, which are connected to the wing via T-pieces.

Experiments

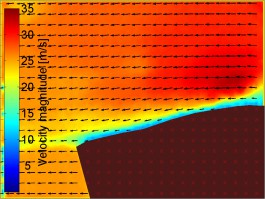

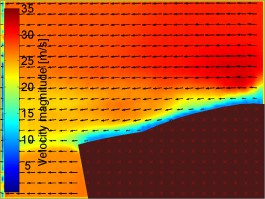

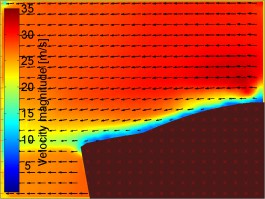

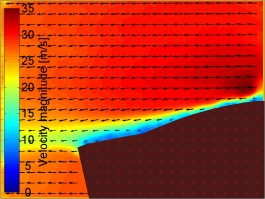

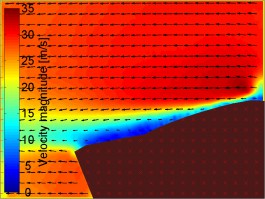

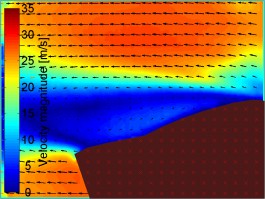

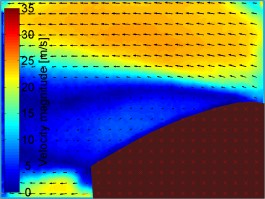

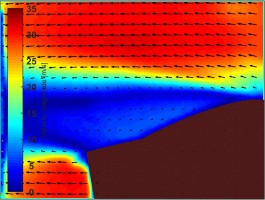

The first tests were to put the wing into operation and demonstrate that it could be used to investigate the stall. PIV measurements were made to measure and visualize the velocity field above the wing. The angle of attack was increased at two constant speeds until the flow stalled. This was done with the stiff flexible profile. On the results you can see that the flexible profile has an influence on the stall.