3d printed Longboard

In the ADP (Advanced design Project) a 3D printed longboard was constructed which was reinforced with glass fiber tapes. The fiber amount and location were optimized with a Fem simulation to save as much weight as possible. Finally, a ridable prototype was built.

Type: Advanced design Project

Institut für Konstruktiven Leichtbau ud Bausweisen (Klub) TU Darmstadt

Year: 2015

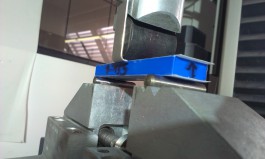

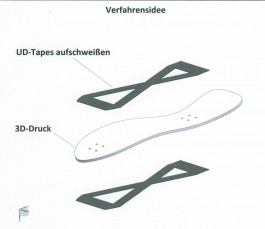

3d Printing and welding process

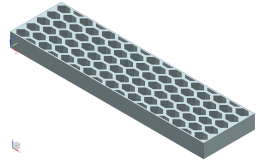

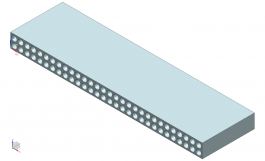

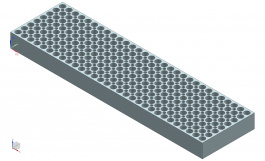

The print material is Abs, which was printed with the Fdm process. The glass fibers are also pre-impregnated with Abs so that both can be welded using a solvent welding process. In the course of the development different welding methods were examined and weighed against each other. The solvent welding process was the most suitable for prototype production. In addition, various structures for the core were investigated.

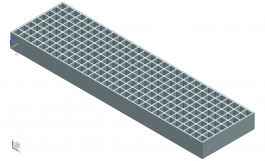

Structural optimization

In order to find out the optimum amount of glass fibers and the best position for them, these were optimized in several iteration steps. The first step was a rough calculation of the fiber directions using the AlphaLam program. Then, in two steps, the main directions of strain were determined in FEM analyses and reinforced with narrow glass fiber Abs tapes.